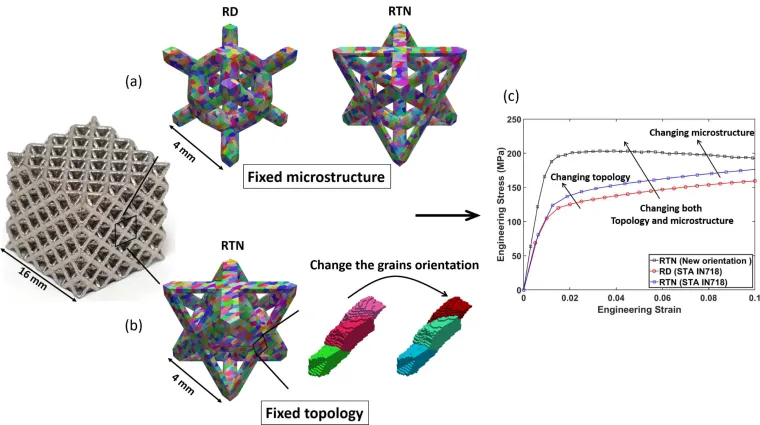

Lattice structures provide an effective means of removing mass from a structure while maintaining desired electromechanical properties. The aggressive development rate of additive manufacturing has opened the door for investigations of complex lattice structures previously unachievable with traditional methods. Our research group aims to investigate the hierarchical relationship between microstructure, topology, and macrostructure present in additively manufactured lattice structures (AMLS). By considering these factors in unison one can create novel, optimized designs that are typically overlooked when considering only topology. Our research aims to understand the underlying deformation mechanisms, and how they control the post-yielding, plateau region, and failure mechanisms in AMLS.

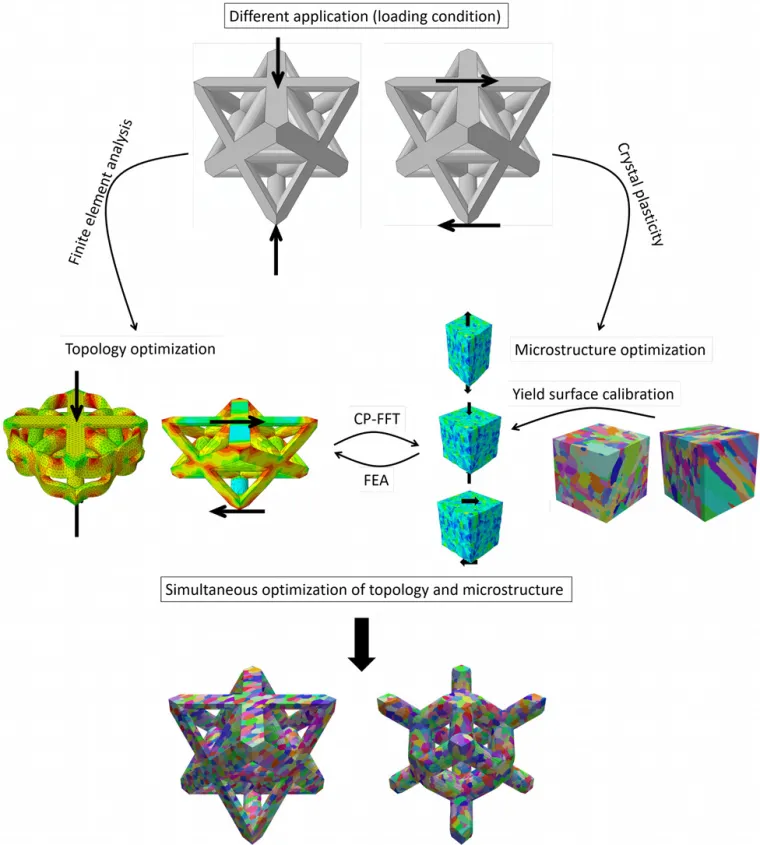

Recent publications [sic] have shown that additive manufacturing processing parameters such as heat treatment and build orientation produce differing microstructures, which can vastly change the macrostructural response of a lattice structure. By performing local crystal plasticity simulations on volume elements representative of the microstructure we can determine a microstructure-specific yield surface for use in FE simulations. This allows us to compare the predicted mechanical properties of various topology and microstructure combinations in order to optimize part design for the intended application.

One ongoing focus of our research is the integration of these concepts into a manufacturing tool wherein industrial workers can provide their desired load conditions and resulting properties and receive an optimized topology/microstructure combination specific to their applications.

This research sponsored by:

Relevant Papers