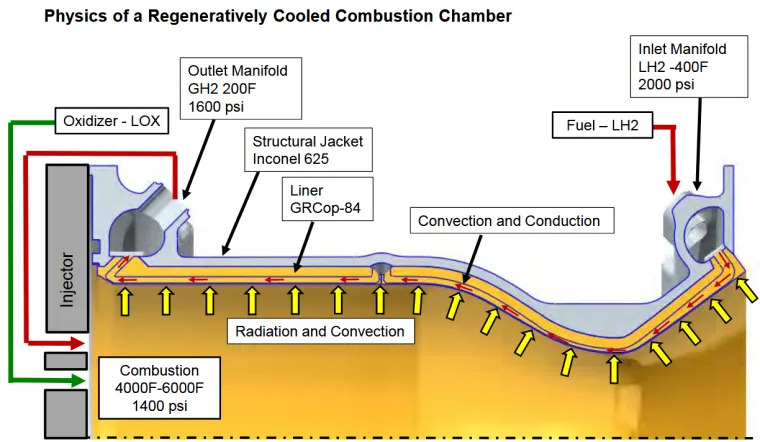

In combustion chambers and similar heat-producing objects, thin-walled structures are used to maximize the surface area for heat transfer and thus achieve the most efficient cooling. The rapid development of additive manufacturing techniques allows us to create thin-walled structures that previously would have required extensive machining or tooling. When printing a specimen that contains very thin walls, one must consider that solidification behavior may differ from that of bulk regions in the sample. This variation in solidification may give rise to a change in physical properties such as porosity, microstructure, surface roughness, etc. These differences can then affect the mechanical performance of the part, so it is important to determine the relationship between wall thickness and resulting characteristics. One material used to produce liner jackets for regeneratively cooled combustion chambers is GRCop-42, a copper-chromium-niobium alloy (Cu-4at% Cr-2at% Nb). In one investigation of GRCop-42 we found that by increases in wall thickness had no noticeable effect on surface roughness, grain size, or texture, although it did decrease porosity by 74.7% in the as-built condition and 99.7% in the hot isostatic pressed (HIP) condition. This decrease in strength results from the formation of crack networks in the more porous thin samples. Another important finding was that SEM imaging showed no crack initiation from the surface roughness, suggesting that crack propagation is facilitated by internal porosity.

This research sponsored by:

Relevant Papers